Alis-Jet Numbering and Braille Controller

The printing of variable data during the finishing process is increasingly popular for pharmaceutical and security labels. The ALIS-Jet group controller automates the multiple ink-jet head configuration and monitoring. The optional camera unit verifies the printed variable data and detects ink-jet malfunction and smear. The screen of the Alis-Jet helps the operator monitor the printing and perform maintenance procedures on the heads from the front of the machine. Integration with rewinder electronics automates tasks like starting a new numbering sequence and printing additional repair sequences. The first label of the sequence is automatically placed on the rewind shaft.

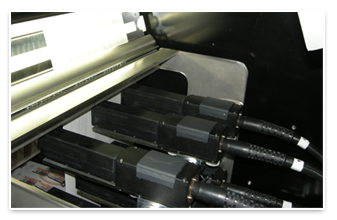

Ink-Jet and Braille Jet Support

The Alis-Jet controller supports most popular continuous, drop-on-demand and Braille printing systems. The standard configuration can control up to 8 heads. Additional 8-heads can be added with an expansion module. All heads are controlled from a single encoder and label sensor. The operation is fully graphical - “what you see is what you get”. Printer fonts are simulated on screen including all special effects – font type, size, bold, dot spacing and different orientations. The position of the variable data is superimposed on the label and is positioned by dragging on the touch screen. Variable data is supported by selection of sequence rules or input of data from a stored data file.

Optional OCR Control

The functionality of the system is enhanced by the optional OCR camera module. The camera unit is mounted immediately after the ink-jet head block monitoring the full width of the web simultaneously. This closed loop control system immediately detects print defects, out of sequence situations and ink-jet head malfunctions. The rewinder is stopped and the risk of wasting the valuable ready labels is minimized. As additional benefit, the operator can monitor on screen the printing and decoded values. The status of the printing system is continuously monitored and displayed. Head malfunction leads to immediate system stop.

Electronic Job Ticket

The electronic job ticket input of the system assists quick job change and configuration. By scanning the bar-code of the factory job ticket, the system retrieves from the MIS server all product data, including numbering position, font, sequence rules and randomized data files. Alis-Jet automatically configures all parameters. The operator must only command the system to start printing and optional inspection. Quality managers can set inspection sensitivity in advance together with the job data. With the full job information, Alis-Jet can additionally prevent a number of finishing mistakes.

Easy to use

No computer knowledge is required to operate a Nikka system. The machines are all equipped with a touch screen, information is displayed graphically and buttons are operated by touching the screen. No mice or keyboards are needed. The machine guides the operator through each procedure. Image on screen exactly matches the image on paper.

Web widths and options

Alis-Jet systems are available for three web widths – 330 mm, 420 mm and 620 mm. Standard configuration can control up to 8 ink-jet heads mounted on three scattered rows. Additional 8 heads can be added by an extension module. The controller can be integrated in new rewinders or retrofitted to existing ones. For retrofits, a range of ink-jet holder modules with retractable frame for easy adjustment and maintenance is available for all popular pharmaceutical rewinders.

Modular, Upgradeable and Reliable

Nikka inspection systems are based on Nikka’s 50 years of experience and innovation in the graphics industry. All machines are modular and field upgradeable for quick repair. One year remote maintenance via secure Internet connection and upgrades is included with each L2 or C2 system. Upgrade packages help keep your Nikka inspection system competitive for years to come.

English

English

Deutsch

Deutsch